Introduction to Electromagnetic Shielding Materials

The rapid proliferation of electronic devices and increasing demand for data integrity create a pressing need for effective electromagnetic shielding materials. Electromagnetic interference (EMI) can disrupt the performance of sensitive electronic equipment, rendering shielding not just optional but essential for ensuring functionality and safety. This article explores the fundamentals of electromagnetic shielding, the materials used, their applications, and the best practices for their implementation.

What is Electromagnetic Shielding?

Electromagnetic shielding refers to the practice of protecting electronic devices from EMI. This interference can arise from various sources, including radio signals, mobile devices, electrical circuits, and even natural phenomena like lightning. The objective of electromagnetic shielding is to either block or attenuate these electromagnetic waves to prevent them from penetrating sensitive components.

Why Use Electromagnetic Shielding Materials?

The increasing interconnectivity of devices has made them susceptible to EMI. By implementing effective shielding, manufacturers can:

- Protect Device Integrity: Shielding helps maintain the functionality of devices, ensuring accurate data transmission and minimizing disruption.

- Enhance Safety: In critical systems such as medical equipment and aviation technology, shielding reduces the risk of catastrophic failures caused by interference.

- Comply with Regulations: Many industries are governed by strict EMI compliance standards to ensure that devices do not emit excessive interference.

- Improve Performance: Implementing proper shielding can lead to improved device reliability and performance.

Common Applications of Electromagnetic Shielding

Electromagnetic shielding materials are utilized in various sectors. Some of the most common applications include:

- Consumer Electronics: Devices such as smartphones, laptops, and televisions often incorporate shielding to prevent interference from wireless signals.

- Telecommunications: Shielding is critical in ensuring signal clarity and minimizing interference in communication equipment.

- Automotive Industry: As vehicles become more technologically advanced, EMI shielding is essential to protect sensitive electronics and ensure safe operation.

- Medical Devices: Shielding is crucial in hospital equipment like MRI machines to avoid interference that could affect readings.

Types of Electromagnetic Shielding Materials

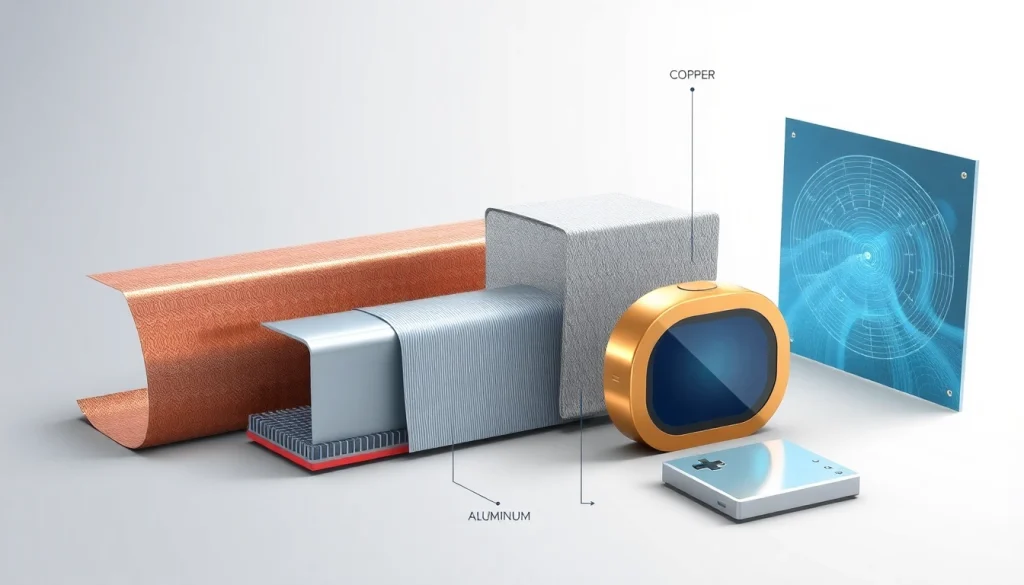

Metal-based Shielding: Copper and Aluminum

Among the most effective materials for electromagnetic shielding are metals, particularly copper and aluminum. These metals possess high electrical conductivity, making them excellent choices for reflective and absorptive shield construction.

Copper

Copper is renowned for its superior shielding properties due to its high conductivity and ability to absorb electromagnetic radiation. It is commonly used in various forms, including:

- Foils: Thin sheets of copper can be applied directly to surfaces for shielding.

- Mesh Screens: Copper mesh can be integrated into designs, allowing for flexibility and ease of installation.

- Plated Components: Components can be plated with copper to enhance their shielding effectiveness.

Aluminum

Aluminum is lightweight and resistant to corrosion, making it a popular choice for applications where weight and durability are critical. It is often used in:

- Enclosures: Aluminum can be fabricated into boxes or cases that house sensitive electronics.

- Foams: Aluminum foams offer both structural integrity and EMI shielding.

Non-metal Options: Conductive Polymers and Nanocomposites

While metals are the most recognized shielding materials, conductive polymers and nanocomposites are emerging as effective alternatives. These materials are often utilized in environments where weight reduction is vital or where flexibility is essential.

Conductive Polymers

Conductive polymers can provide effective shielding while being lightweight. They are often used in:

- Coatings: Polymers can be applied as a coating on surfaces to provide EMI shielding.

- Flexible Components: Integrated into flexible circuits, conductive polymers can enhance EMI resistance without sacrificing design.

Nanocomposites

Nanocomposites combine traditional materials with nanoscale components to enhance their shielding properties. These materials are often tailored for specific applications and can offer superior electromagnetic attenuation. Common structures include:

- Carbon Nanotubes: Known for their mechanical strength and electrical conductivity, these can be incorporated into various materials.

- Graphene-Based Composites: Graphene, with its remarkable conductivity, provides additional strength and functionality when combined with plastics or other materials.

Comparing Effectiveness of Different Materials

The effectiveness of electromagnetic shielding materials can be assessed through several parameters, including:

- Shielding Effectiveness (SE): This is a measure of a material’s ability to attenuate electromagnetic fields, generally expressed in decibels (dB).

- Frequency Range: Different materials perform better at specific frequency ranges, necessitating a careful selection based on application.

- Thickness: Shielding effectiveness can increase with material thickness, though this may also add weight and bulk to the device.

Copper often leads the pack in SE, followed closely by aluminum, while conductive polymers can provide adequate shielding in lightweight applications.

Application Techniques for Electromagnetic Shielding

Choosing the Right EMI Shielding Method

When selecting an EMI shielding method, consider factors like the environment, desired performance level, and material properties. Common methods include:

- Shielded Enclosures: Fully fabricated boxes made from metal (often copper or aluminum) that house electronic components.

- Coatings: Applications of conductive paint or sprays that provide shielding without additional bulk.

- Gaskets and Seals: Used in enclosures to ensure continuity and effectiveness of shielding by minimizing gaps where EMI could penetrate.

Installation Best Practices for Shielding Materials

The installation of electromagnetic shielding materials greatly influences their effectiveness. Following best practices ensures optimum performance:

- Ensure Proper Grounding: Effective grounding of shielding materials can significantly enhance performance and reduce the likelihood of EMI entry.

- Avoid Gaps: Seamless application of shielding materials is crucial; any gaps can serve as entry points for interference.

- Consider Environmental Factors: Temperature, moisture, and chemical exposure can affect material performance. Choosing materials resistant to such conditions is vital.

Common Mistakes to Avoid in Shielding Applications

Even with the right materials, mistakes during application can compromise shielding effectiveness:

- Using Incompatible Materials: Ensure compatibility between different shielding materials and underlying surfaces to avoid degradation.

- Ignoring Layout Design: The geometric arrangement of shields can affect performance; a layout that considers the electromagnetic environment is essential.

- Neglecting Maintenance: Regular checks on the integrity of shielding materials can help assess ongoing effectiveness and help identify issues early.

Performance Metrics and Effectiveness

Testing Standards for Electromagnetic Shielding

Standardized testing ensures that electromagnetic shielding materials meet desired performance metrics. Testing methods such as ASTM D4935 and IEEE 299 assess both the shielding effectiveness and conduct similar parameters:

- ASTM D4935: This standard measures the shielding effectiveness of materials in the microwave frequency range.

- IEEE 299: Primarily used for measuring shielding effectiveness in cables and enclosures.

Measuring Shielding Effectiveness

Shielding effectiveness is typically quantified in decibels (dB), using the formula:

SE(dB) = 10 log10(Pin/Pout)

Where Pin is the power incident on the shield, and Pout is the power transmitted through it. A higher dB value signifies better shielding capability, essential for performance evaluation across various applications.

Improving Performance with Layered Approaches

Layered shielding approaches can enhance overall effectiveness. By combining several materials, such as using metal foil along with conductive polymers, one can mitigate weaknesses in individual materials and enhance overall performance. Examples include:

- Multi-layer Foils: Combining different metals can enhance shielding across various frequency bands.

- Composite Layering: Utilizing different materials based on their properties (like flexibility, weight, and cost) can yield optimal results for specific applications.

Future Trends in Electromagnetic Shielding Materials

Innovations in Material Science for EMI Shielding

As industries evolve, so does the research in electromagnetic shielding materials. Emerging innovations focus on:

- Graphene and Nanotechnology: Advanced materials like graphene offer outstanding conductivity and strength, paving the way for next-gen shielding solutions.

- Sustainable Materials: Developing eco-friendly and safe alternatives without compromising performance continues to be a priority.

- Smart Materials: The integration of smart materials that can adjust their properties based on environmental changes is an exciting frontier in EMC technology.

Sustainable Practices in EMI Shielding Material Production

The environmental impact of traditional shielding materials has led to increased focus on sustainability. Using recycled materials and developing biodegradable options can meet compliance while reducing ecological footprints:

- Using Recyclable Metals: Favoring metals that can be easily recycled minimizes waste and energy consumption in production.

- Biodegradable Composites: Research is ongoing into composites that decompose without environmental harm, achieving both performance and sustainability.

Market Trends and Consumer Demand for Shielding Solutions

The demand for effective electromagnetic shielding is growing, driven by trends such as:

- Increased Regulation: Regulatory bodies continue to implement stricter EMI standards across industries, pushing for better shielding solutions.

- Consumer Electronics Boom: With the rise of smart devices, manufacturers are seeking innovative shielding materials to enhance user experience.

- Growing Awareness of Health Effects: There is increasing consumer awareness of potential health impacts from electromagnetic waves, fueling demand for effective shielding technologies.