The Basics of Soft Grippers

What is a Soft Gripper?

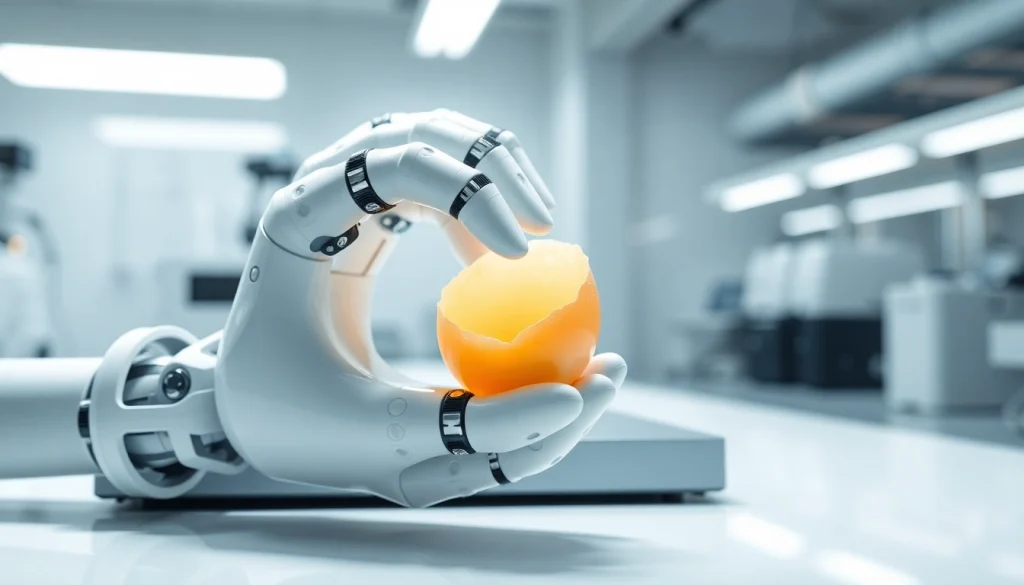

A soft gripper is an innovative tool utilized in robotics, leveraging the principles of soft robotics to pick and manipulate delicate objects. Unlike traditional rigid grippers that can be harsh and unyielding, soft grippers are designed to adapt their shape and texture, allowing them to grasp items without damaging or crushing them. The core functionality of a soft gripper often involves pneumatic or hydraulic actuators that inflate and deflate, mimicking the gentle grasp of a human hand. This technology opens doors to applications in various industries, from agriculture to food processing, where precise handling of sensitive items is crucial.

Key Components and Materials

At the heart of a soft gripper’s design are several key components and materials that contribute to its functionality:

- Actuators: Soft grippers commonly utilize air-filled or fluidic actuators, which allow movement and adaptation to the shape of the object being grasped.

- Materials: Many soft grippers are made from elastomers, silicone, or other flexible polymers that can stretch without losing their structural integrity. These materials enable a balance between strength and flexibility.

- Embedding Sensors: Some advanced designs incorporate sensors that provide feedback about grip force and contact conditions, enhancing performance and safety.

Benefits of Using Soft Grippers

The advantages of soft grippers are numerous, making them a popular choice across various sectors:

- Gentle Handling: Soft grippers can delicately handle fragile objects like fruits, eggs, and electronics.

- Adaptability: They can adjust their shape and grip based on the size and texture of the object.

- Safety: The flexible design reduces the risk of damaging both the gripper and the items being handled.

- Versatility: Soft grippers can be used in diverse applications, ranging from food and beverage processing to surgical robots.

Design Considerations for Soft Grippers

Factors to Consider in Design

When designing a soft gripper, several factors must be taken into account to ensure effectiveness and efficiency:

- Payload Capacity: Designers must calculate the maximum load the gripper will need to handle without compromising its performance.

- Grip Force: It’s vital to establish how much force is required to pick and hold objects securely without damage.

- Range of Motion: The design should allow for sufficient movement to accommodate objects of various shapes and sizes.

- Environmental Conditions: The materials used may need to withstand specific temperatures or humidity levels depending on operational environments.

Common Materials Used for Soft Gripper Fabrication

Various materials are employed in the fabrication of soft grippers, each with unique properties suited for specific tasks:

- Silicone Rubber: Offers excellent flexibility and durability, often used for food-safe applications.

- Thermoplastic Polyurethanes (TPUs): Provide a balance of elasticity and strength, making them suitable for more demanding environments.

- Elastomers: These flexible materials allow for stretchability while maintaining a robust structure, making them ideal for gripper fingers.

Prototyping and Testing Techniques

Prototyping and testing are vital phases in developing effective soft grippers:

- 3D Printing: Rapid prototyping technologies allow for quick iterations of gripper designs, enabling developers to test and refine their prototypes effectively.

- Finite Element Analysis (FEA): This computer-based technique helps simulate how designs will behave under real-world conditions, allowing for adjustments in design before physical prototyping.

- Testing Grip Strength and Durability: Conducting experiments to determine the maximum load a gripper can handle and its lifespan under repetitive usage is crucial for ensuring reliability.

Applications of Soft Grippers

Industries Utilizing Soft Grippers

Soft grippers have found applications across various industries, including:

- Agriculture: Soft grippers are increasingly used in harvesting delicate fruits and vegetables to minimize bruising and injury.

- Food Processing: Automation in the food industry benefits from soft grippers in tasks such as packaging and sorting delicate items.

- Healthcare: In medical robotics, soft grippers are often employed in surgical tools that require precision and care for human tissue.

Case Studies of Successful Implementations

Several companies and research institutions have successfully integrated soft grippers into their processes:

- Harvesting Robots: Companies like FFRobotics have developed robots equipped with soft grippers that can harvest fruits with various surfaces without damage.

- Food Packaging Solutions: OnRobot has designed soft grippers for food handling, allowing for safe, quick, and accurate packaging processes that enhance productivity.

- Robotic Surgery: The use of soft grippers in surgical robots has shown a marked reduction in tissue damage during procedures, allowing for faster patient recovery times.

Challenges and Solutions in Real-World Applications

While the benefits of soft grippers are clear, challenges still exist:

- Grip Reliability: Ensuring consistent grip strength can be difficult. Solutions include embedding sensors to provide real-time feedback on grip performance, allowing for adjustments during operation.

- Material Handling: Different materials can interact unpredictably. Using customizable molds and varying material properties helps address this issue.

- Cost Implications: The production costs must be considered against the potential returns. Developing modular designs can optimize costs and improve deployment flexibility.

Future Trends in Soft Gripper Technology

Advancements in Material Science

The field of material science is evolving, leading to new materials for soft gripper construction. Innovations include:

- Bioinspired Materials: Researchers are developing materials mimicking natural organisms, enhancing adaptability and performance.

- Smart Materials: These materials can change properties in response to environmental stimuli, providing advanced functionality for soft grippers.

Integration with AI and Machine Learning

As AI technology advances, the integration with soft grippers can lead to smarter automation systems:

- Real-Time Learning: Soft grippers can learn and adapt to different objects, improving efficiency and effectiveness over time.

- Automated Quality Control: AI can help in monitoring the quality of items being handled and ensure consistency in performance.

Emerging Markets and Opportunities

Soft grippers are poised to enter new markets, presenting various opportunities:

- Environmental Applications: As sustainability becomes a priority, soft grippers can be integral in recycling processes and eco-friendly packaging solutions.

- Personal Robotics: The demand for personal assistant robots can leverage soft grippers for household tasks, enhancing user experiences.

How to Build Your Own Soft Gripper

Step-by-Step Fabrication Process

For those interested in creating a soft gripper, here’s a simple guide:

- Design Your Gripper: Use software like CAD to create your gripper design tailored to your specific needs.

- 3D Printing the Mold: Print a mold of your design using a suitable material that can withstand silicone casting.

- Prepare Silicone Mixture: Mix the silicone rubber according to the manufacturer’s instructions to ensure optimal curing.

- Pour Silicone into Mold: Carefully pour the mixture into your 3D printed mold and allow it to cure as recommended.

- Testing: After curing, test the gripper using various objects to ensure it meets design specifications. Adjust as necessary.

Tools and Techniques You’ll Need

Here’s a list of tools and techniques essential for building your own soft gripper:

- 3D printer for mold creation

- CNC machine for precise cuts (optional)

- Silicone rubber and mixing tools

- Pneumatic components (if applicable) for actuation

Common Mistakes to Avoid

To ensure a successful build, be aware of these common pitfalls:

- Inadequate Material Selection: Ensure chosen materials are appropriate for the intended application.

- Overthinking Design: Keep the design simple initially to avoid complications during testing stages.

- Neglecting Testing: Always conduct thorough tests before using your gripper in real-world applications to refine performance.